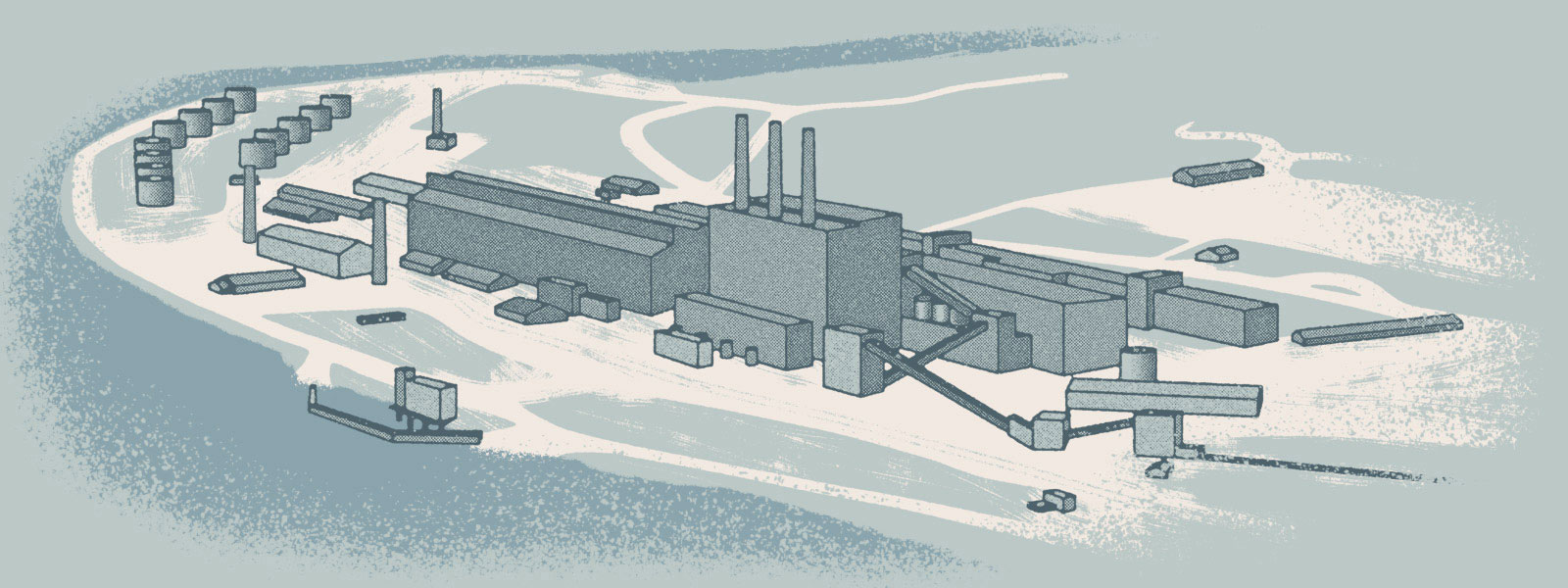

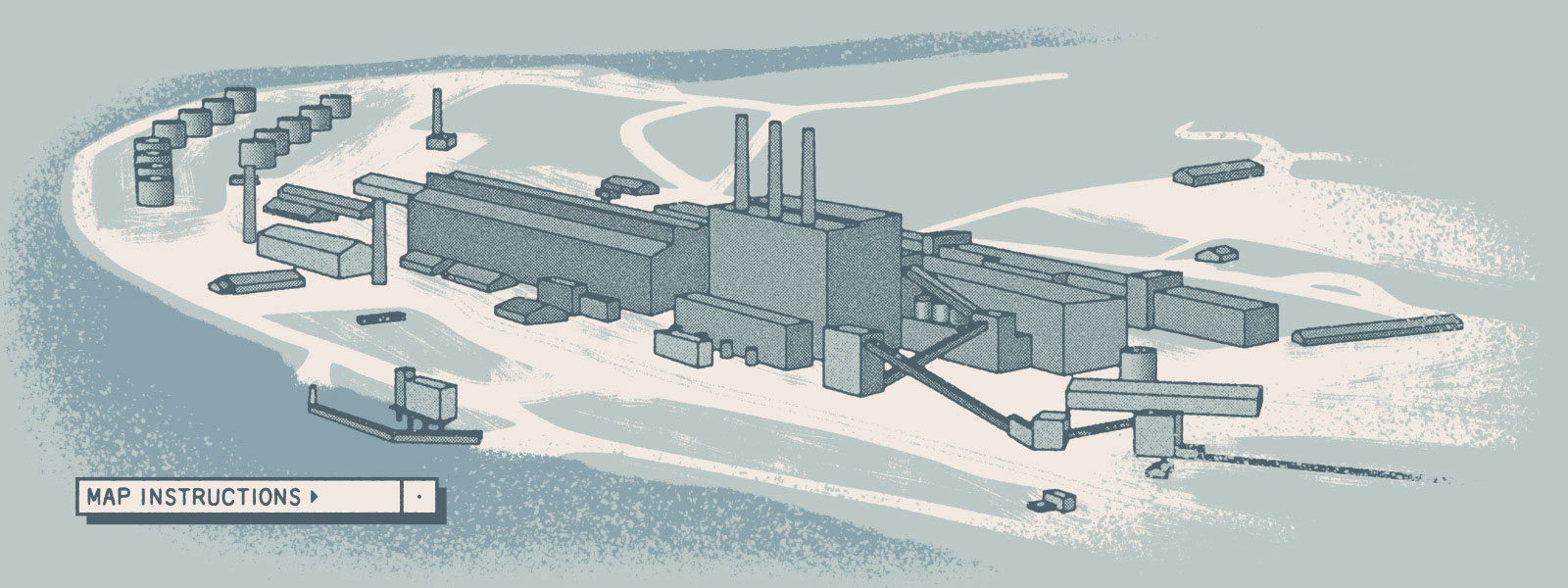

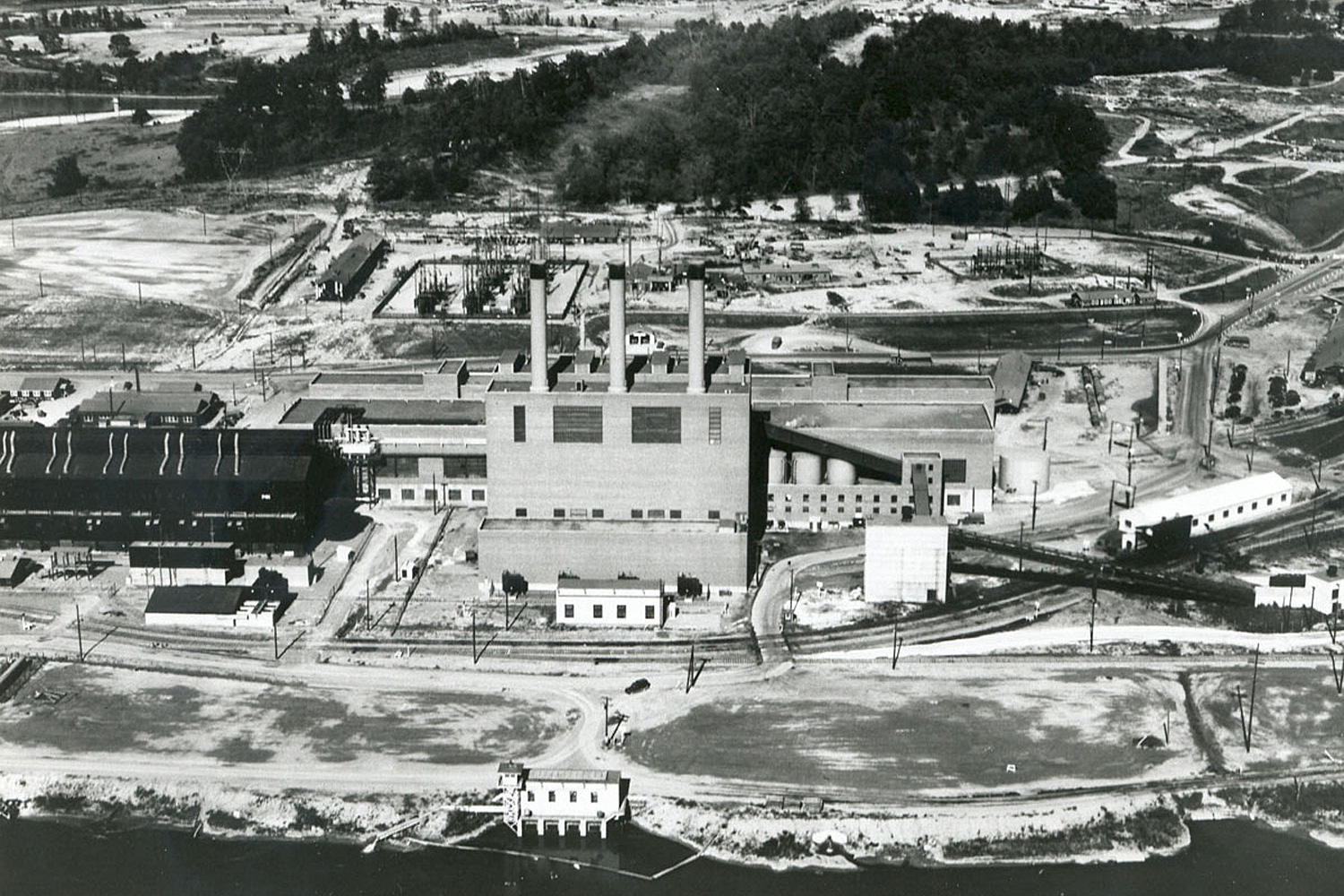

POWER HOUSE AREA / S-50

The Manhattan Project's urgent mission resulted in building construction beginning before process system designs were finalized. In particular, mechanical engineers did not yet know the rotating speed of the compressors required to operate the enrichment process. Electrical engineers addressed the uncertainty by designing and constructing a dedicated Power House capable of generating variable frequency power.

Domestic power in the United States was (and is) generated at 60 cycles per second (60 Hertz). The K-25 Power House would generate power at variable frequencies from 45-65 Hertz as well as constant frequency power at both 60 Hertz and 120 Hertz. Consequently, frequencies (and compressor rotating speeds) were varied until the designers determined optimal power distribution for the process. Ultimately, K-25 systems could operate at 60 Hertz in all sections except one, which ran at 120 Hertz.

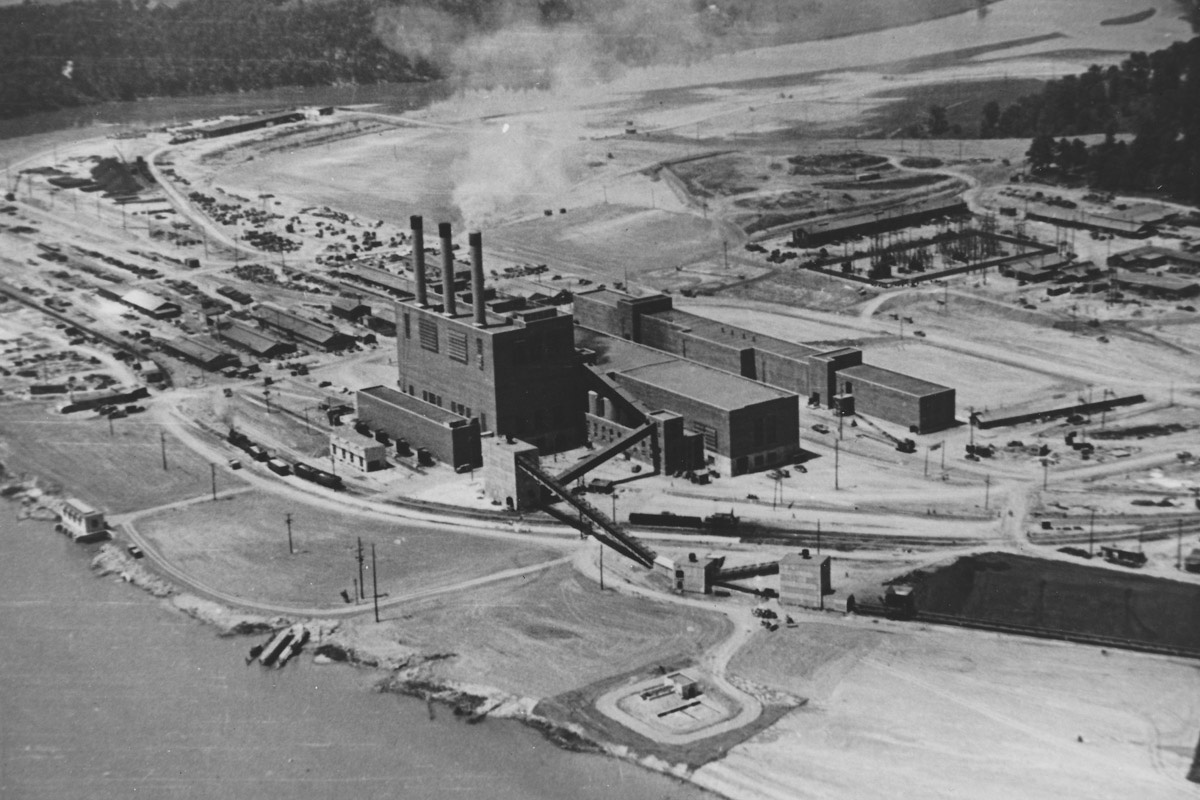

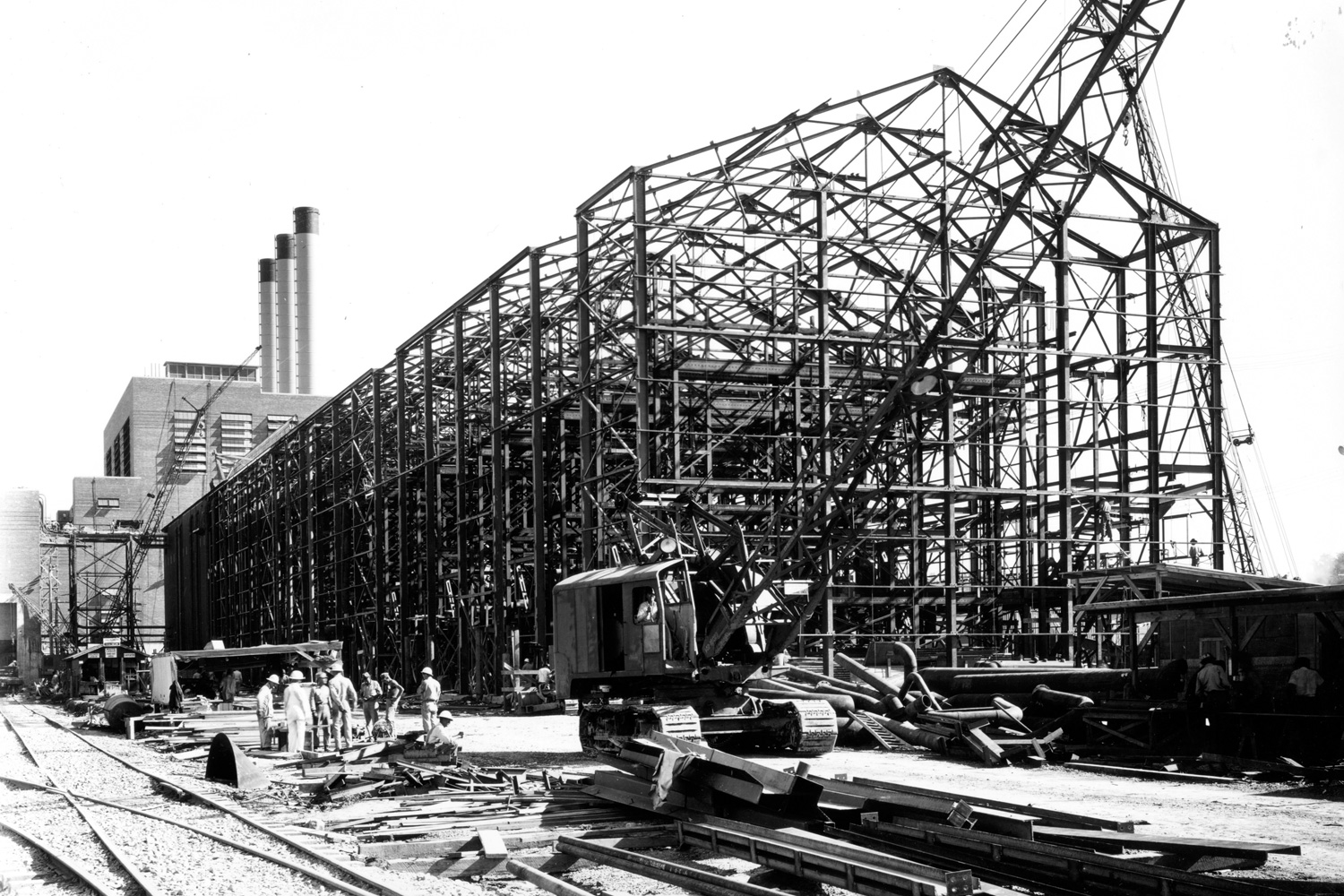

Ground was broken to begin construction of the K-25 Power House on June 1, 1943; the pouring of the first concrete footers occurred later that month. Erection of the first boiler commenced in October 1943, and the first systems testing was conducted on March 9, 1944. The first turbine was erected in mid-December 1943 and was in service by April 15, 1944.

In total, the Power House complex included more than 15 structures. Descriptions of key buildings are provided below.

K-701 Boiler House

The boiler house contained three coal-fired boilers and operating offices. Each boiler was designed to produce 750,000 pounds per hour of steam at 1,325 pounds per square inch at a temperature of 935 degrees Fahrenheit.

K-702 Turbine Room

The steam generated by the three boilers in K-701 was piped to 14 turbine generators with a combined rating of 238,000 kilowatts. By comparison, Tennessee Valley Authority's (TVA) Norris Dam in neighboring Anderson County, has a generating capacity of 132,000 kilowatts. The average American household consumes nearly 11,000 kilowatts each year.

K-704 Main Switch House

The power from the generators was routed via underground feeder cables to the K-704 Main Switch House through air circuit breaker buses and on to the K-25 process building through 13 underground conduits.

K-707 Auxiliary Switch House

The auxiliary power to drive the many fans, coal pulverizes, conveyors, water pumps, intake screens, and other equipment was obtained from the transformers and switchgear in the auxiliary switch house.

K-706 Pump House

Water needed for the boilers, turbine condensers, and other equipment was obtained from the Clinch River. This water flowed through an underground tunnel to the K-706 Pump House, where it was then pumped to the needed equipment.

Coal Storage Yard

Coal for the Power House was brought in by rail and stored in the K-708-F Coal Storage Yard. The yard could store up to 250,000 tons of coal. The coal was transported from the yard by conveyor in the bunkers on the north side of K-701 Boiler House.

The Power House could also receive and regulate power supplied by TVA. By 1960, TVA supplied significant amounts of the electricity to the site enrichment processes. Consequently, decommissioning of onsite power generating facilities began in the mid-1960s with equipment removal from K-701 and K-702 Buildings by 1967. Power House facilities were finally demolished in 1995.

In 1940, the Uranium Committee elected not to pursue liquid thermal diffusion as a uranium enrichment option. Vannevar Bush, Director of the Office of Scientific Research and Development, revisited the process in 1942 but again concluded not to pursue. Initially, little production data was available on the process; later, research and pilot testing originated in the Navy, which posed administrative and security complications in the transfer to an Army-managed effort. But in summer 1944, as gaseous diffusion barrier difficulties continued and broad concerns over meeting production deadlines grew, the liquid thermal diffusion process of separating uranium received a second chance.

On July 6, 1944, H.K. Ferguson Company of Cleveland, Ohio, broke ground on a liquid thermal diffusion plant called S-50. The plant was to serve as a feeder process to the electromagnetic plant, Y-12. By Halloween 1944 (just 69 days after starting construction), Ferguson, through its wholly owned subsidiary, Fercleve, had completed construction and simultaneously delivered its first uranium product to Y-12. By April 1945, the gaseous diffusion plant, K-25, was producing uranium material at 1.1 percent enrichment, higher than S-50 product output. At this point, S-50 direct shipments to Y-12 were discontinued; the plant's entire output became uranium feeder material for the K-25 process.

The liquid thermal diffusion process was based upon the theory that molecules containing light isotopes (U235) tend to move in the direction of rising temperature, while other molecules containing heavier isotopes (U238) move in the direction of falling temperature. To achieve separation of the isotopes, the process requires that the walls of the diffusion container be kept at different temperatures, vertical, and very close together. A series of 21 racks, each containing 102 columns, were installed in the F-01 Thermal Diffusion Process Building. The 2,142 columns each consisted of three concentric tubes. Steam was fed through the inner tube; uranium hexafluoride was fed between the walls of the inner and second tube; and once-through cooling water circulated through the region between the second and outer tube.

S-50 was originally powered with steam from the Power House Complex. As the massive K-25 gaseous diffusion plant came online and more steam was required, a new steam plant, F-06, was built to provide a supplemental steam source. S-50 had several other support facilities, including the F-02 Pump House, F-03 Water Treatment Plant, F-04 Switch House, F-05 Laboratory No. 2, F-07 Material Shop, F-08 Laboratory No. 1, and the F-10 Machine Shop.

Post-war assessment determined that gaseous diffusion was the most productive and economical method of uranium enrichment. Consequently, the S-50 plant was shut down in September 1945 and demolished in 1947.